Key Strengths

Key Strengths

Professional technical team

In line with its long-term innovation-driven development strategy, Henan Pingyuan Intelligent Equipment Co., Ltd. (hereinafter referred to as “Pingyuan”) has implemented a talent strategy that combines self-cultivation with introduction. This has attracted high-end experts from both domestic and foreign markets to join the technical team through methods such as external recruitment and technical consultants, leading to continuous improvement in the company’s R&D, design, and management capabilities. These resources provide a solid talent base and technical support for project implementation and company growth.

High-tech enterprise

As a national high-tech enterprise, Pingyuan’s technology center has been identified as Henan Provincial Enterprise Technology Center, Henan Provincial Industrial Design Center, Henan Province Engineering Technology Research Center, and Municipal Key Laboratory. Our company has been awarded the title of Henan Province Specialized, Refined, Differential and Innovative SME.

Research and development (R&D) center

Pingyuan has established a fully functional test center, an automotive coating equipment laboratory specifically for researching new coating technologies, processes, and materials, which integrates R&D, testing and verification, and publicity and demonstration functions. With a building area of more than 3,000 m2, the test center covers an area of more than 4,000 m2.

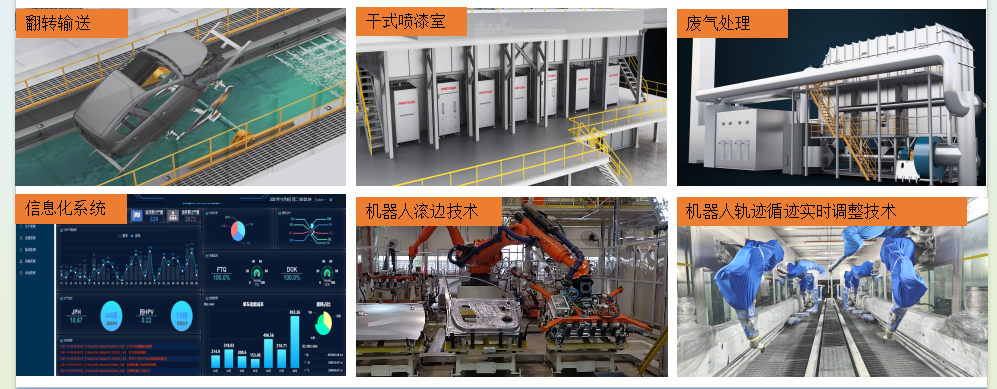

Advanced technology

Through continuously implementing the innovation-driven development strategy, our company has increased R&D investment and achieved a stream of R&D achievements in recent years, including more than 30 advanced core technologies in the industry, such as flip conveyor, dry spray booth, air recirculation, waste gas treatment, information-based system, robot hemming technology, and robot trajectory tracking real-time adjustment technology.

Patents and works

Through continuously implementing the innovation-driven development strategy, our company has increased R&D investment and achieved a stream of R&D achievements in recent years, including more than 30 advanced core technologies in the industry, such as flip conveyor, dry spray booth, air recirculation, waste gas treatment, information-based system, robot hemming technology, and robot trajectory tracking real-time adjustment technology.

Talent advantage

Talents are the core resources for enterprise development. Our company has excellent talents, which is the key to maintain competitiveness and innovation capability, including 180+ technical R&D staff, 1,000+ project implementation staff, 40+ senior project managers, and 60+ senior engineers.

5S management

Seiri: Differentiate items in the workplace and keep the needed items.

Seiton: Arrange items neatly by category in their designated positions and label them.

Seiso: Remove dirt from the workplace and keep the workplace clean and tidy.

Seiketsu: Institutionalize, standardize, implement and maintain the 3S approach.

Shitsuke: Develop the habit of following rules and cultivate a proactive spirit.

Modularization

Modular standardized production, is convenient and efficient, improves product integrity, facilitates project installation and reduces project construction period.

Salvagnini

The Salvagnini automatic flexible sheet metal production line is a high-end mechanical equipment that integrates sheet metal punching, bending and forming. It can produce an average of one plate per minute and the product accuracy can be controlled to 0.05 mm per meter.

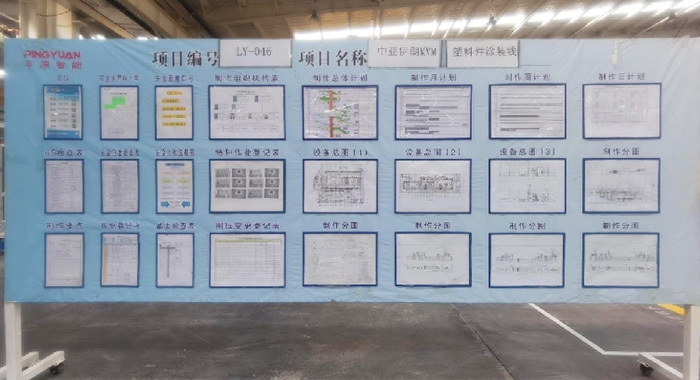

Visual management

Project progress management can be clearly and intuitively displayed, simplifying the management tasks of managers and supervisors and improving efficiency, enhancing the skills of on-site managers and supervisors, and monitoring project status in real time.

Standardized management

Unifying the requirements for installing equipment, creating consistent installation effects, and standardizing staff construction standards.

Test line

The advancement of the FLIP-360° conveyor is that it adops 360° flip over conveyor method to replace the horizontal conveyor method. By using a 360° flip method for PT & ED, the defects of surface particle deposition and cavity air chambers caused by the traditional conveyor methods can be completely avoided, thus improving the quality of coating. At the same time, it can reduce the length of the production line by about 30%, save floor space and civil engineering investment, and reduce the energy consumption of public ventilation and air exchange in the workshop. The dry spray booth uses paper filter material to replace the traditional water-steam mixed method for overspray treatment, which can effectively reduce spray costs and reduce the emission of the Three Wastes.